Featured Products

-

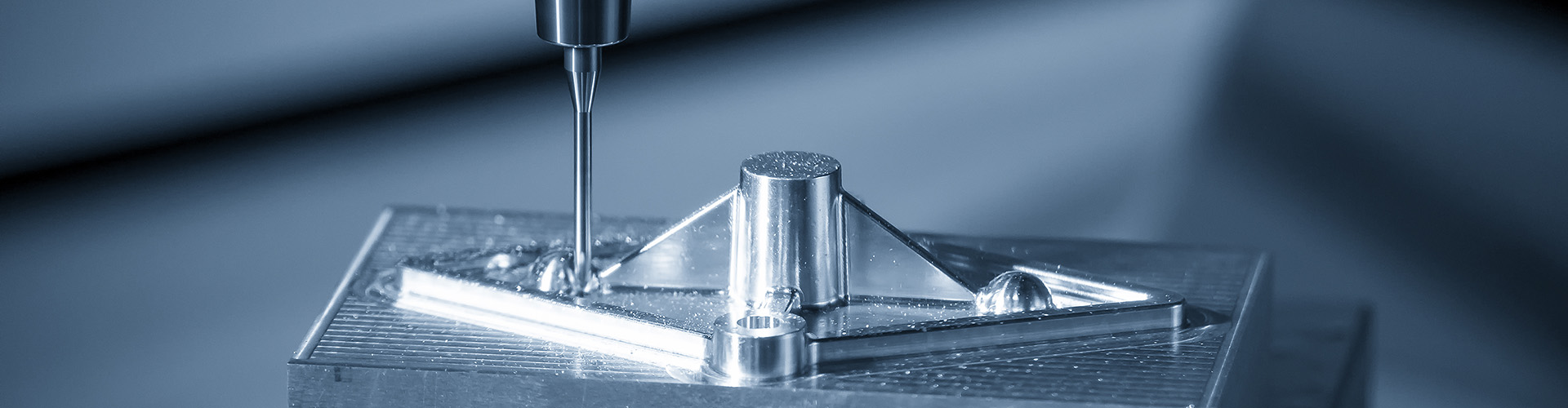

High Precision Metal Lathe Machining CNC Parts

Turning/Lathe Machining Services:

1. Machining round parts.

2. Mainly uses a turning tool to turn a rotating workpiece.

3. Used for drills, reamers, taps, dies and knurling tools.

4. High speed and high precision.

-

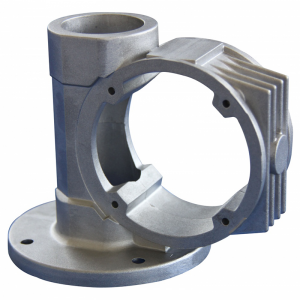

OEM Metal Die Casting Process Sample Production

The die-casting process is a process of unifying pressure, speed and time by using three major elements: machine, mold and alloy.

-

OEM Customized CNC Milling Turning High Precision Metal Parts

Product Name: OEM customized high precision product

Service Type: OEM

Dimension: Customized parts according to customers’ drawing file

Process ways: CNC Milling+Turning

Certificate: ISO9001:2015

Place of Origin: Guangdong, China

MOQ: 1 Piece

Supply Ability: 3000-20000 Pieces per month (it depends on the product’s structure)

Tolerance: About +/-0.005mm

Available Material: Plastic and metal material can be found in the market.

-

3D Printing Resin Model Prototype

3D printing is usually achieved using digital technology material printers. It is often used to make models in fields of mold manufacturing, industrial design, etc., and is gradually used for the direct manufacturing of some products.

Tolerance

SLA:+/-0.05mm

SLS:+/-0.2mm

Metal Printing:+/-0.1mm

-

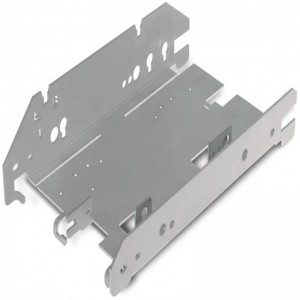

Laser Cutting Machining Punched Bending Welding Stamping Plate Parts

Laser cutting is digital making methods available online Laser cutting is a subtractive manufacturing technology that uses a high-power laser beam to cut flat-sheet materials, such as sheet metal. A computer directs this laser to follow the cutting line provided in your digital design.

-

Low Volume Production Vacuum Casting Mold Plastic Parts

Product Name: Custom polyurethane vacuum casting parts

Service Type: OEM

Dimension: Customized customers’ drawing

Process: Vacuum Casting, Urethane Casting, Silica Gel Mould, Rapid Silicon prototype

Certificate: ISO9001:2015

Place of Origin: Guangdong, China

Format: STP, STEP, IGS, STL, X-T

Quantity: One silicone mold can produce 10-12 PCS parts

Supply Ability: 5000-50000 Pieces per month (it depends on the product’s structure)

Tolerance: +/-0.1 mm

Available Material: Liquid resin