Featured

-

New Fashion Design for 5 Axis CNC Machining - China Transparent Acrylic PMMA Plastic Parts CNC Turning Machining – Huachen

PC Smoked Process Smoking PC parts with the chemical materials for a reach a transparent effect seemingly same as PAAM, as PC parts is not enough transparent likes as PAAM after polishing only. Plate a coating on the object under the confition of high temperature then it will be depositing a pretty effect in the plastic surface. Application 1. Architectural applications: shop windows, soundproof doors and windows, lighting covers, telephone booths, etc. 2. Advertising app... -

Best Price on Custom Parts - High Precision Metal Lathe Machining CNC Parts – Huachen

What is CNC Turning Machining? Lathe processing is a part of mechanical processing. Lathe machining mainly uses turning tools to turn the rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with revolving surfaces, and are the most widely used type of machine tool in machinery manufacturing and repair factories. Benefits of... -

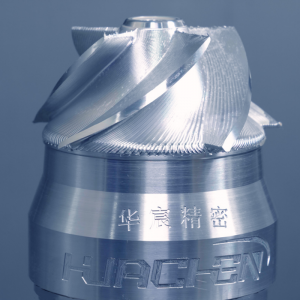

Chinese Professional Precision CNC Milling - Five Axis CNC Machining Compressor Wheel 7075 Aluminum Alloy – Huachen

Profession & Better 5 Axis CNC Maching Our company passed ISO9001:2015 quality management system certification. Five-axis machining provides infinite possibilities as to the part sizes and shapes you can effectively process. It is widely used in the automotive industry for prototyping or production of car components. Moreover, it is available on all manner of titanium and aluminum aerospace parts. Instruments, high-precision medical equipment and other industries have a pivotal ... -

Best-Selling Aluminum CNC Service - High Precision Metal Lathe Machining CNC Parts – Huachen

What is CNC Turning Machining? Lathe processing is a part of mechanical processing. Lathe machining mainly uses turning tools to turn the rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with revolving surfaces, and are the most widely used type of machine tool in machinery manufacturing and repair factories. Benefits of... -

Manufacturer for Customized Prototype - Low Volume Production Vacuum Casting Mold Plastic Parts – Huachen

Vacuum complex mode refers to the use of the existing prototype, by making a silicone mold, using silicone mode under vacuum pouring liquid resin, copy the prototype. There are so many types of liquid resin that their performance is different, through this method can obtain different properties of parts. Hardness: Silicone rubber, also called TPU, shore hardness is 20 to 90℃. Maximum Size: 1200mm*1000mm*1000mm Surface Treatment: Grinding, Polishing, Spray Paint, Sandblast(Bead Blast), Si... -

Factory wholesale Automotive Prototype - Low Volume Production Vacuum Casting Mold Plastic Parts – Huachen

Vacuum complex mode refers to the use of the existing prototype, by making a silicone mold, using silicone mode under vacuum pouring liquid resin, copy the prototype. There are so many types of liquid resin that their performance is different, through this method can obtain different properties of parts. Hardness: Silicone rubber, also called TPU, shore hardness is 20 to 90℃. Maximum Size: 1200mm*1000mm*1000mm Surface Treatment: Grinding, Polishing, Spray Paint, Sandblast(Bead Blast), Si... -

18 Years Factory CNC Engineering - High Precision Metal Lathe Machining CNC Parts – Huachen

What is CNC Turning Machining? Lathe processing is a part of mechanical processing. Lathe machining mainly uses turning tools to turn the rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with revolving surfaces, and are the most widely used type of machine tool in machinery manufacturing and repair factories. Benefits of... -

Hot Sale for Industrial Prototyping - Low Volume Production Vacuum Casting Mold Plastic Parts – Huachen

Vacuum complex mode refers to the use of the existing prototype, by making a silicone mold, using silicone mode under vacuum pouring liquid resin, copy the prototype. There are so many types of liquid resin that their performance is different, through this method can obtain different properties of parts. Hardness: Silicone rubber, also called TPU, shore hardness is 20 to 90℃. Maximum Size: 1200mm*1000mm*1000mm Surface Treatment: Grinding, Polishing, Spray Paint, Sandblast(Bead Blast), Si... -

Cheapest Price Quick Parts - High Precision Metal Lathe Machining CNC Parts – Huachen

What is CNC Turning Machining? Lathe processing is a part of mechanical processing. Lathe machining mainly uses turning tools to turn the rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with revolving surfaces, and are the most widely used type of machine tool in machinery manufacturing and repair factories. Benefits of... -

Factory source Precision CNC Parts - High Precision Metal Lathe Machining CNC Parts – Huachen

What is CNC Turning Machining? Lathe processing is a part of mechanical processing. Lathe machining mainly uses turning tools to turn the rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with revolving surfaces, and are the most widely used type of machine tool in machinery manufacturing and repair factories. Benefits of... -

Renewable Design for Aluminium Prototyping - Low Volume Production Vacuum Casting Mold Plastic Parts – Huachen

Vacuum complex mode refers to the use of the existing prototype, by making a silicone mold, using silicone mode under vacuum pouring liquid resin, copy the prototype. There are so many types of liquid resin that their performance is different, through this method can obtain different properties of parts. Hardness: Silicone rubber, also called TPU, shore hardness is 20 to 90℃. Maximum Size: 1200mm*1000mm*1000mm Surface Treatment: Grinding, Polishing, Spray Paint, Sandblast(Bead Blast), Si... -

Low MOQ for Rapid Prototyping And Engineering - Low Volume Production Vacuum Casting Mold Plastic Parts – Huachen

Vacuum complex mode refers to the use of the existing prototype, by making a silicone mold, using silicone mode under vacuum pouring liquid resin, copy the prototype. There are so many types of liquid resin that their performance is different, through this method can obtain different properties of parts. Hardness: Silicone rubber, also called TPU, shore hardness is 20 to 90℃. Maximum Size: 1200mm*1000mm*1000mm Surface Treatment: Grinding, Polishing, Spray Paint, Sandblast(Bead Blast), Si...