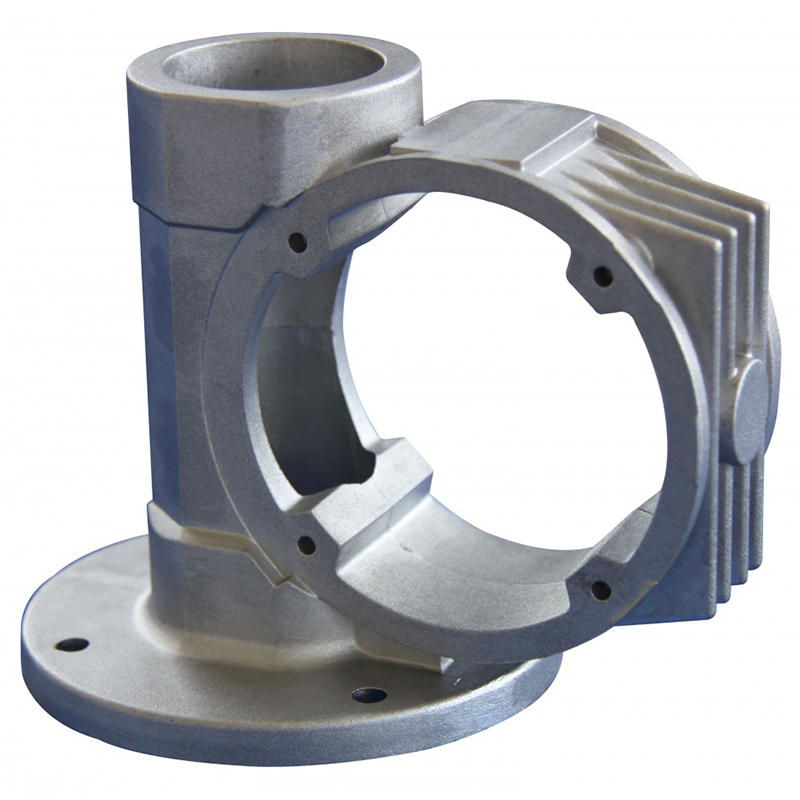

Good Quality Urethane Casting - Professional Manufacturing Custom Injection Molding Plastic Products – Huachen

Good Quality Urethane Casting - Professional Manufacturing Custom Injection Molding Plastic Products – Huachen Detail:

Profession & Better

| Product Description | ODM plastic injection molding |

| Plastic Materials | ABS, Nylon6, Acrylic, PBT, PEEK, PLA, PPS, PVC, HDPE, PEI, PC-PBT, PPE-PS, PSU, LDPE, PET, TPE, TPV |

| Other Materials | Rubber, Silicone, Aluminum, Zinc, Copper, Metal, etc. |

| Feature | Non marking and Non flash |

| Standard | ISO9001-2015 |

| Export Country | Europe, Japan, America, Australia, UK, Canada, France, Germany, Italy, etc. |

| Experience | 10 years experience in plastic injection mold making and plastic products produce. |

| To Be Discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold, etc. |

| Mould Base | Husco Standard, European Standard, World Standard |

| Surface Finish | Texture(MT standard), High gloss polishing |

| Equipment | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder |

Package

We are dedicated to delivering the most high-quality and beautiful parts to meet your expectations.

Three layers of protection are applied to the package

1. Wrapping paper

2. Foam

3. Paper/Wooden box

Advantages

Injection Molding has the most variable options for materials, colors and configurations when compared to CNC machining or 3D printing

1. Excellent production speed

2. Low cost per part

3. High precision

4. Excellent surface finishes

5. Exceptional strength

6. Multi-material manufacturing

Product detail pictures:

Related Product Guide:

We have advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for Good Quality Urethane Casting - Professional Manufacturing Custom Injection Molding Plastic Products – Huachen , The product will supply to all over the world, such as: Paris, New York, Serbia, Our Company policy is quality first, to be better and stronger, sustainable development . Our pursuit goals is for society, customers, employees, partners and enterprises to seek reasonable benefit. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top