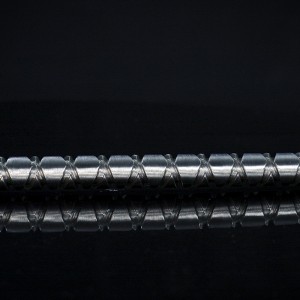

High Precision Metal Lathe Machining CNC Parts

What is CNC Turning Machining?

Lathe processing is a part of mechanical processing. Lathe machining mainly uses turning tools to turn the rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. Lathes are mainly used to process shafts, discs, sleeves and other workpieces with revolving surfaces, and are the most widely used type of machine tool in machinery manufacturing and repair factories.

Benefits of CNC Turning

CNC Turning is best if you are looking to create fast and repeated symmetrical or cylindrical parts with a high production volume.

CNC Turning can produce parts of high quality and an extremely smooth finish. CNC turning is also capable of:

Drilling

Boring

Reaming

Taper turning

Feature for Turning Machined Parts

Lathe parts are applicable to a wide range of electronic appliances, hardware tools, toys, plastic and other industries. Compared with other rugged parts, its main feature is high precision and tolerance up to plus or minus 0.01mm. Of course, its price is relatively much higher than other solid pieces.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top