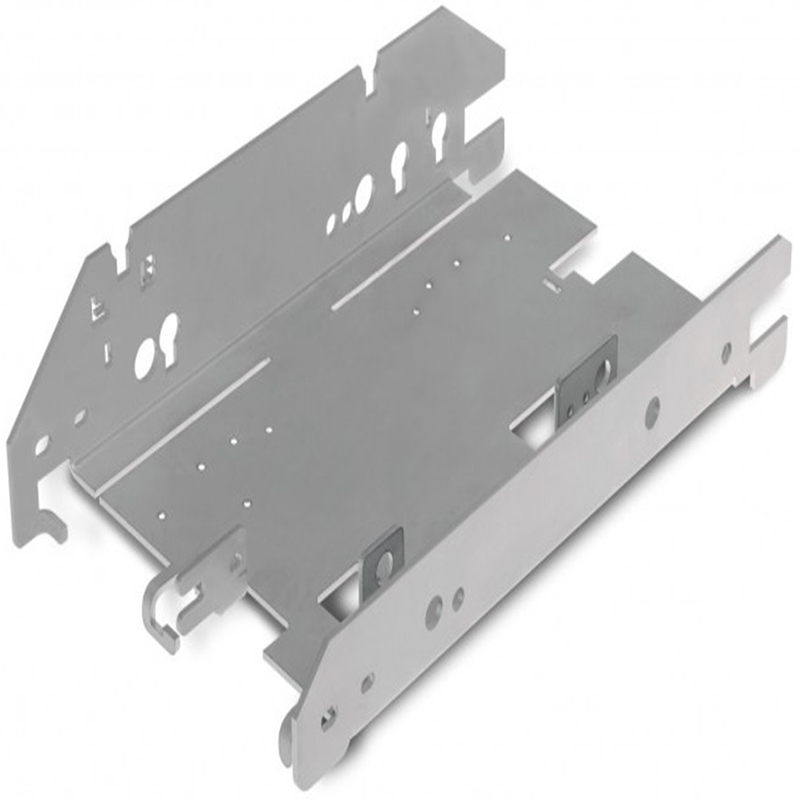

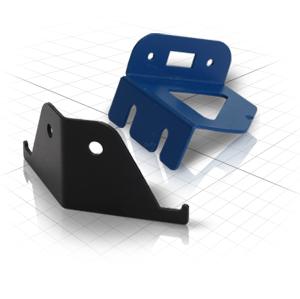

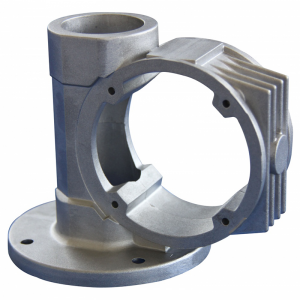

Laser Cutting Machining Punched Bending Welding Stamping Plate Parts

The high-precision laser vaporizes a cut line through the sheet metal, leaving a 90-degree high-quality cut-edge. Sheet metal bending is vital process in manufacturing industry, and is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same. In some cases bending technology may bring a small change in sheet thickness. For most operations, it will produce basically no change in the thickness. In addition to creating a desired geometric form, bending is used to impart strength and stiffness to sheet metal, to change a part's moment of inertia, for cosmetic appearance and to eliminate sharp edges. The production of prototyping sheet metal parts consists of shaping a sheet of metal (foldable material obtained by laser cutting) to give it the desired shape and appearance. We perform the different operations of shaping and folding, punching, stamping and assembly by welding. Various different finishes can be applied (painting, anodizing, etc.). The use of these different processes depends on the selected material, the thickness of the sheet used (according to the desired application of your prototypes or small series) and the selected shape.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top