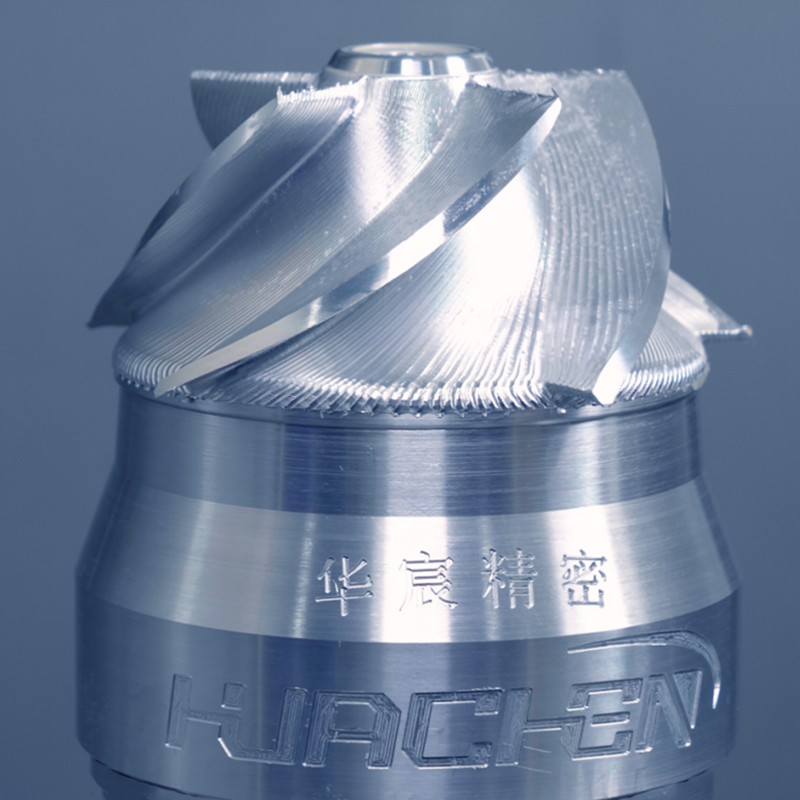

Low MOQ for Cnc Engraving Machining - Five Axis CNC Machining Compressor Wheel 7075 Aluminum Alloy – Huachen

Low MOQ for Cnc Engraving Machining - Five Axis CNC Machining Compressor Wheel 7075 Aluminum Alloy – Huachen Detail:

Profession & Better

5 Axis CNC Maching

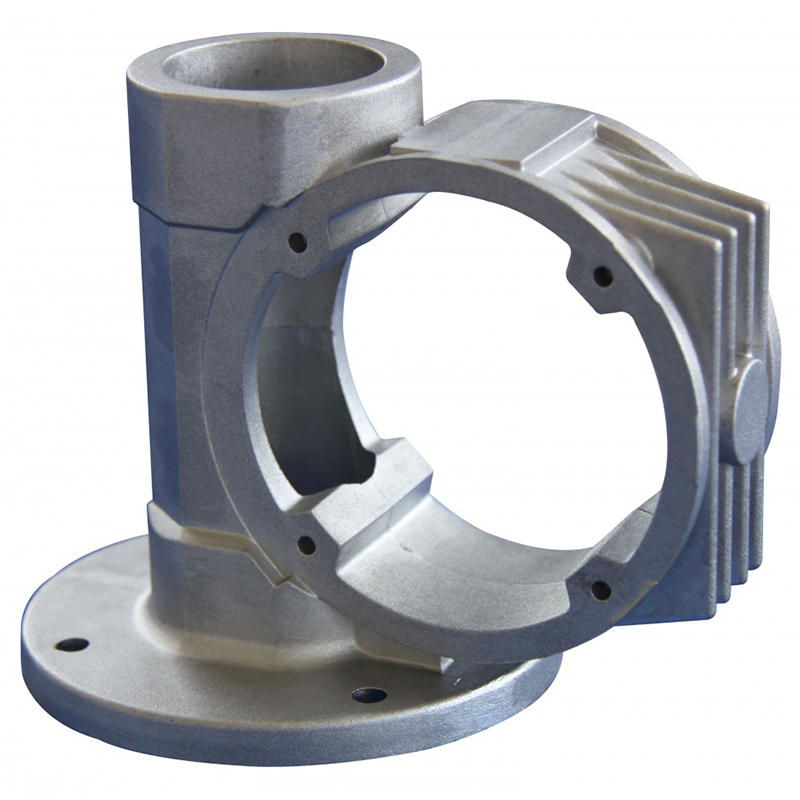

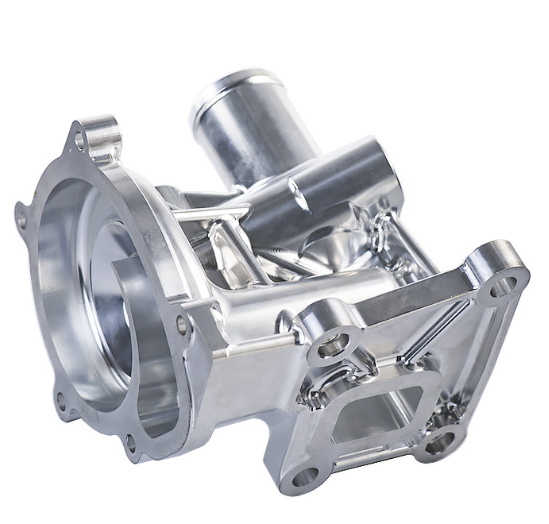

Our company passed ISO9001:2015 quality management system certification. Five-axis machining provides infinite possibilities as to the part sizes and shapes you can effectively process. It is widely used in the automotive industry for prototyping or production of car components. Moreover, it is available on all manner of titanium and aluminum aerospace parts. Instruments, high-precision medical equipment and other industries have a pivotal influence. We have expert engineers operating 5 Axis CNC Machines to mill aluminium, steel, titanium, copper, brass, engineering plastics and many more materials into complex shapes quickly. The part is worked on a 5-axis machining center, the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the workpiece from any direction. In other words, you can process five sides of a part in a single setup.

The part of the post-treatment is hard anodized (black). Hard Anodized is common finishing treatment. It is mainly the anodic oxidation of aluminum, which uses the principle of electrochemistry to form a layer of Al2O3 (aluminum oxide) film on the surface of aluminum and aluminum alloys. This layer of oxide film has special properties such as protection, decoration, insulation and wear resistance.

Of course, focusing metal components, we can do quite well with many kinds of post-treatments.

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Low MOQ for Cnc Engraving Machining - Five Axis CNC Machining Compressor Wheel 7075 Aluminum Alloy – Huachen , The product will supply to all over the world, such as: Muscat, Bangladesh, Bandung, Create Values,Serving Customer! is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top