What is Metal Die Casting?

Die Casting refers to the process of producing metal parts formed by a mold. This process allows products to be made on a mass production scale with high quality and repeatability. The process begins by forcing molten metal under high pressure into a cast died. The die can contain one or many cavities (cavities are the molds that create the part shape). Once the metal solidified (as quick as 20 seconds) then the die opened and the shot (gates, runners and parts all connected) are removed and the process begins again. Following the die casting operation, the shot is usually processed further on a trim die where the gates, runners and flash are removed. Then the part can be processed further by vibratory deburring, shot blasting, machining, painting, etc.

Advantages Of Die Casting

Aluminum die casting is the most common process to produce aluminum casting parts used in diverse industries. As aluminum has an excellent material flowability, highly corrosive resistance and high dimensional stability with complex parts shaped.

Aluminum die casting part is high mechanical strength, easy to cast, and has a lower cost compared to zinc or magnesium die casting parts.

Aluminum die casting parts have great physical properties that withstand a high temperature, which makes aluminum casting could be used in automotive, airplane, medical, and other industrial products.

Five Steps

Step 1. Material Melting

Since aluminum has a very high melting point (660.37 °C) that can’t be melted inside a die casting machine directly. This is why we need to pre-melted it with a furnace that is attached to a die casting machine.

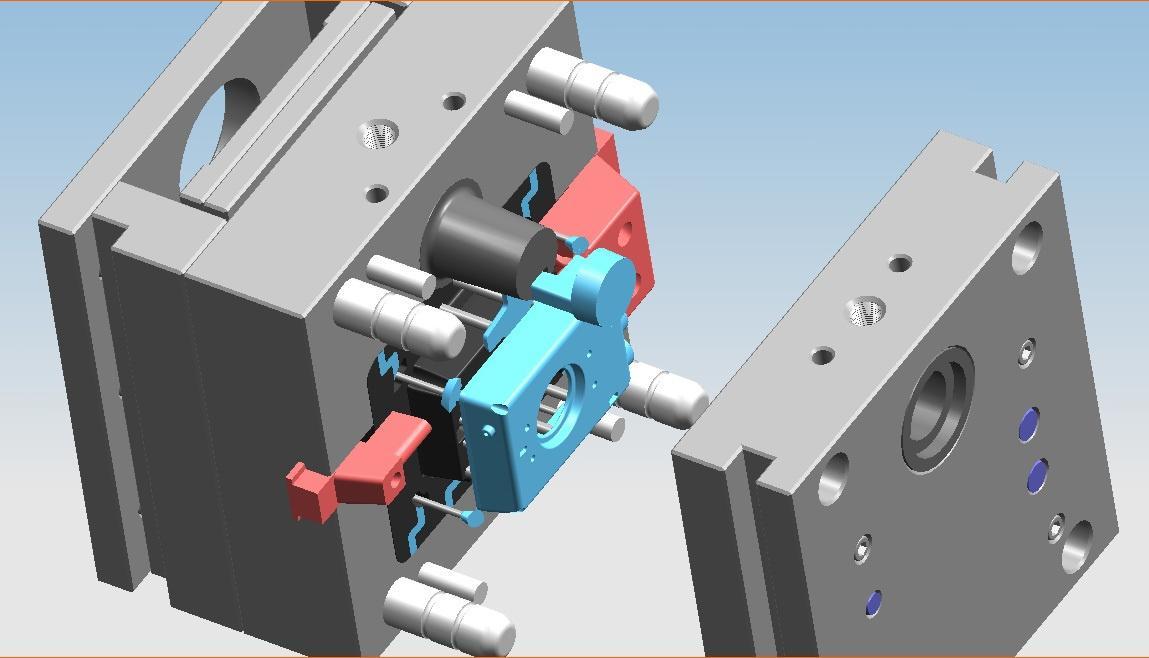

Step 2. Mold Tool Mounting and Clamping

It’s almost similar to injection molding, the die casting process also needs a mold tool for the casting process. Therefore, we need to mount the die casting mold tool on a cold die casting machine.

Step 3. Injection or Filling

The molten material is transferred from the furnace to die casting machine by a moveable ladle. In this stage, the material will be poured and forced into the die casting mold cavity where the material cools and solidifies to obtain desired to die casting products.

Step 4. Cool and Solidification

After the die casting mold tool is fully filled with molten material, it takes 10 ~50 seconds to cool and solidify( it depends on part structure and size).

Step 5. Part Ejection

When the mold opens, the casted parts would be ejected off by ejection pins from die casting mold tool. Then the raw casted parts are ready.

Die Casting Parts Showcase

Custom Die Casting Part

Die Casting Part Without Finshing Treatment

Functional Die Casting Part

Mass Production Die Casting Parts

Rapid Prototype Tooling Part